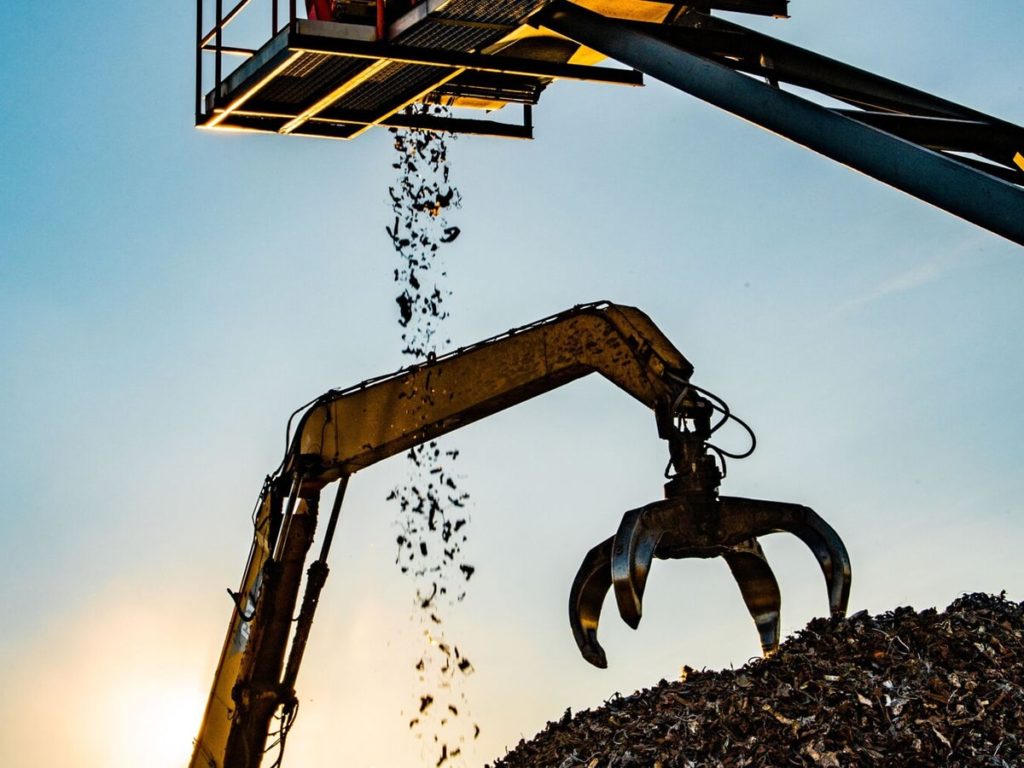

Our team at Integrated Shredder Technology has been involved in the sale and installation of some of the most successful and productive shredding operations in the world. These shredding operations feature heavy duty fabrication with extra steel and reinforcement in demanding wear and impact areas.

In addition to heavy duty fabrication, we offer details and features that ease in the replacement of manganese casings and other AR wear liners. We integrate top of the line manufacturers from our hydraulics systems to our shredder controls and automation. All of these details add up to a reliable and high production shredding operation.

In addition to full shredder systems, IST offers several other key components of a shredding operation;

- Heavy duty infeed conveyors utilizing D4 undercarriage components. Drive options include hydraulic motor or a mechanical style drive with gearbox and electric motor.

- Double and Single Feedroll Assemblies utilize heavy duty frames featuring 36″ to 60″ diameter feedroll drums up to 2″ in thickness. IST Feedroll drums feature internal support ribs as well as AR400 feedroll “bars” or “teeth”. The shredder feedroll also offers options for hydraulic as well as mechanical drive.

- IST feed chutes feature heavy duty beam support structure with cross bracing. All high wear areas (beneath the lower feedroll and lower sidewalls) feature replaceable AR 400 liners. IST offers options for shredder subframes, supporting both the feed chute and shredder.

IST ferrous down streams feature some of the industry’s most durable and heavy-duty fabrication. From proven conveyor designs that last decades, to magnet stands and efficient air systems that consistently produce clean shredded scrap, IST fabrication facilities have manufactured some of the most proven systems in the world.

IST engineering offers flexible custom designs to meet any requirement, whether it be a specialty low copper shred or demanding environmental regulations.

IST offers a full range of nonferrous recovery solutions. We pride ourselves on offering custom solutions for your metal recovery needs.

Many vendors want to push a “canned” solution or offer technological solutions that are years old. At IST we listen to your needs, understand your goals, and offer practical and affordable solutions to increase your metal recovery.

From green field installations to retrofit projects, IST designers utilize years of experience to design the right metal recovery plant to meet your requirements.

We not only maintain relationships with the industry’s leading suppliers of metal recovery equipment, we are constantly looking for new technologies to offer and improve your nonferrous system.

IST offers proven, quality manganese and alloy castings for your shredding operation. We offer a large selection of shredder castings for most OEM shredder models and our pattern shop is always available for new casting designs.

We offer many hammer versions, single and double beam grate designs, as well as large “drop-in” front wall liners, back walls, top grates and reject doors. IST also offers rotor caps, end disc caps and sideliner packages.

In addition to standard lead times, IST offers an expedited service for quick, emergency deliveries.

Contact IST today for your wear part needs!

IST is a supplier of key shredder aftermarket components to keep your shredding operation running smoothly. Listed below are just some of the items IST supplies on a regular basis.

- Bearings and Seals

- Bearing Housings

- Infeed Conveyor Parts (D4 Rollers, Track Pads, Nuts/Bolts, D4 Chain)

- Sprockets- Feedroll and Infeed Conveyor Sprockets

- Hydraulic Cylinders-Feedroll, Reject Door, Mill tilt cylinder

- Hydraulic Power Units and Motors, Bearing Lube Units

- Liner Bolts/Nuts, Bearing Bolts, Anvil Bolts

- Hammer pins

- Tie Rods

- Reject Door Blocks, Inserts and Spacers

IST field personnel possess the technical expertise and experience for trouble shooting as well as facilitating the installation of new shredding equipment. From rotor bearing installation, to hydraulic system trouble shooting, IST can help you save valuable time in getting your shredding operation back online. Contact us today to schedule for assistance.

In addition to our standard shredder system package, IST offers several eco-friendly options for demanding environmental regulations and requirements. The following include but are not limited to;

- VOC Burner Systems (Blue Smoke Machine)

- Shredder Enclosure

- Sound Abatement Systems (Sound walls)

- Safety Cage

- Closed Loop Air System (Zero Bleed)

- Bag Houses

Often installations may require one or all these options to secure permitting. IST works with several environmental companies who specialize in permitting assistance to the metal recycling industry.

Note: We want to thank Photohunter.net for some of the images applied to this page.