Introduction–The IST Difference

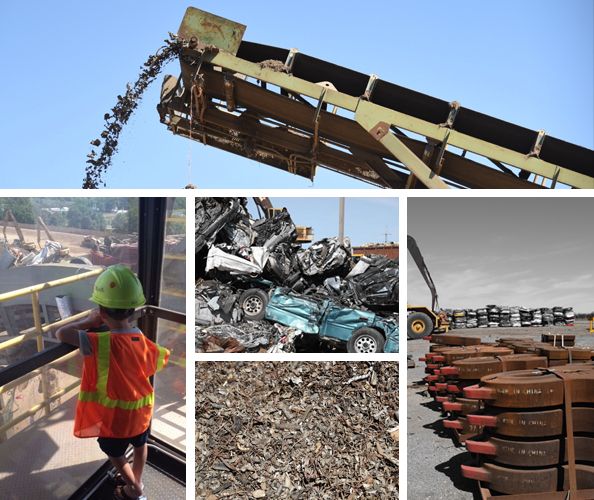

Integrated Shredder Technology is a full-service supplier to the automobile shredding industry. Our right-sized staff has over 100 years of combined sales, engineering, and installation experience. IST offers a full range of shredder castings and wear parts as well as after -market components.

We pride ourselves on a streamlined quotation process, quick response time, and custom solutions to meet your shredding needs.

Our projects range from complete shredding systems as well as ferrous and non -ferrous downstream solutions.

Our Mission

Integrated Shredder Technology is dedicated to providing metal processing expertise when planning, collaborating, and partnering with clients to design a solution that targets their needs and solves their problems.

Our Vision

Recycling today for tomorrow’s future.

Our Leadership

Scott McGlothlin

Scott McGlothlin graduated from Texas A&M University in 1994 where he received his BS in Mechanical Engineering. His vast experience includes lead engineer at Texas Shredder, where he was integral in designing the 122 shredder as well as numerous other shredding operations throughout the world. Scott served as VP Technology for Metso Recycling in which he developed innovative solutions for nonferrous recovery as well as designing one of the industries’ flagship plants. His true passion is to discover, develop, and integrate all available nonferrous technologies and products to supply the customer with a best fit solution. Scott has over 20 years in the scrap metal processing Industry.

Chad Grohman

Chad Grohman graduated in 1996 with a BBA from Baylor University. His first job was with Texas Shredder as a regional sales manager for the Gulf Coast Region. His territory grew to include the West Coast/Southwest US, and Mexico. Chad has been involved in the sale and installation of some of the industries’ most cutting edge shredding operations. He served as VP Sales North America at Metso Recycling where he continued to develop relationships and knowledge of the industry. He has worked for over 20 years with scrap customers to provide solutions to their shredding and metal processing needs.